- Overview

- Product Description

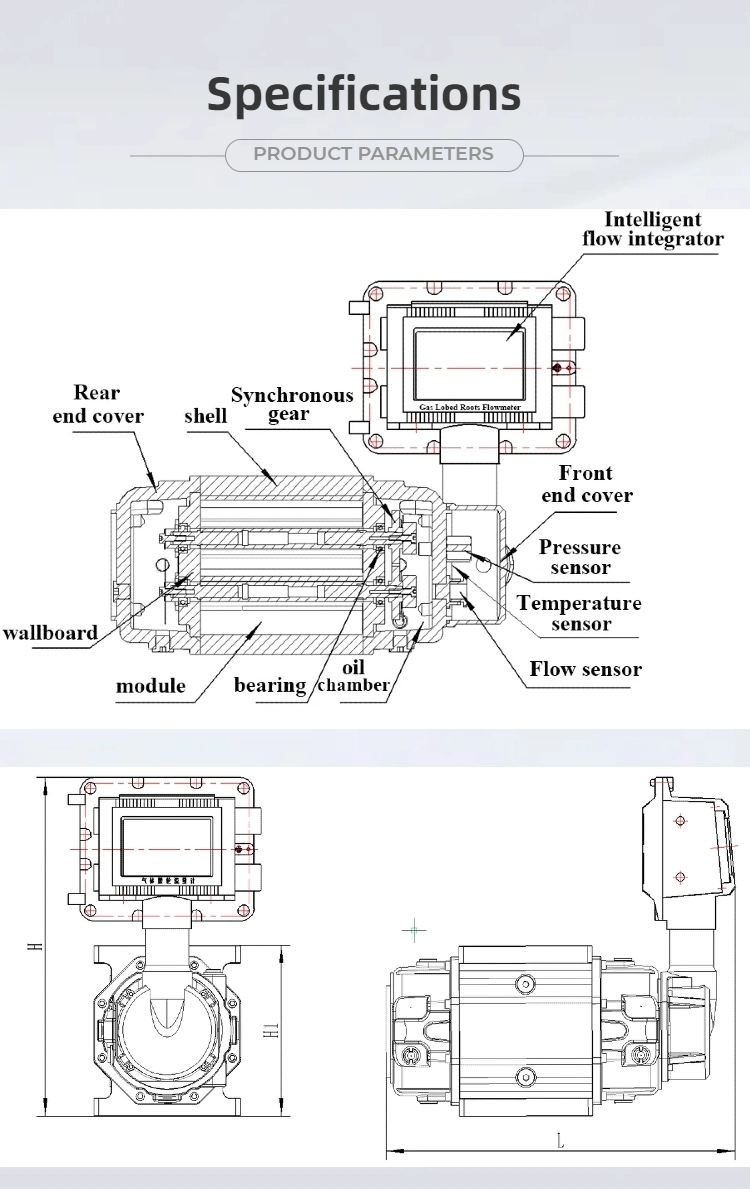

- Product Parameters

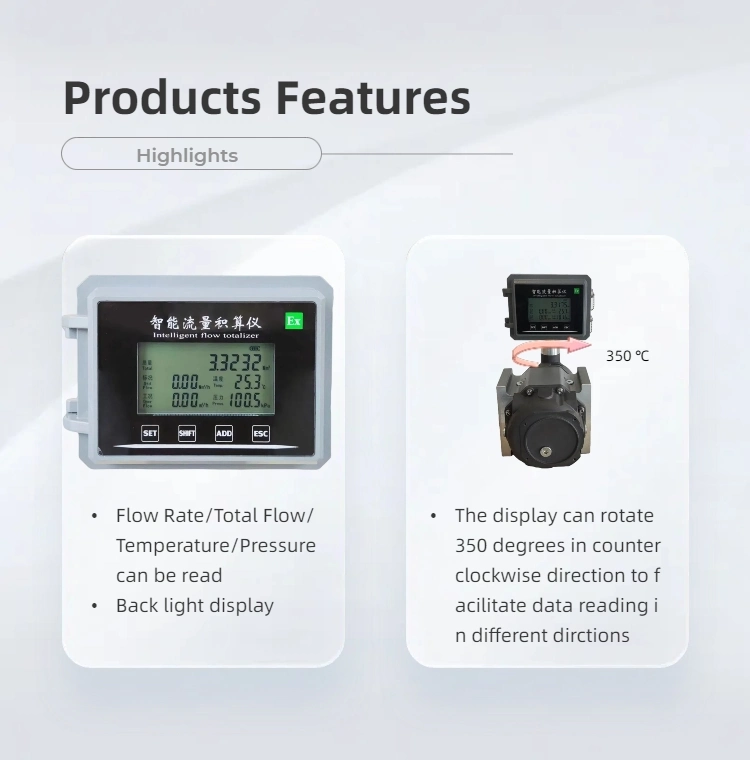

- Detailed Photos

- Installation Instructions

- Model Selection

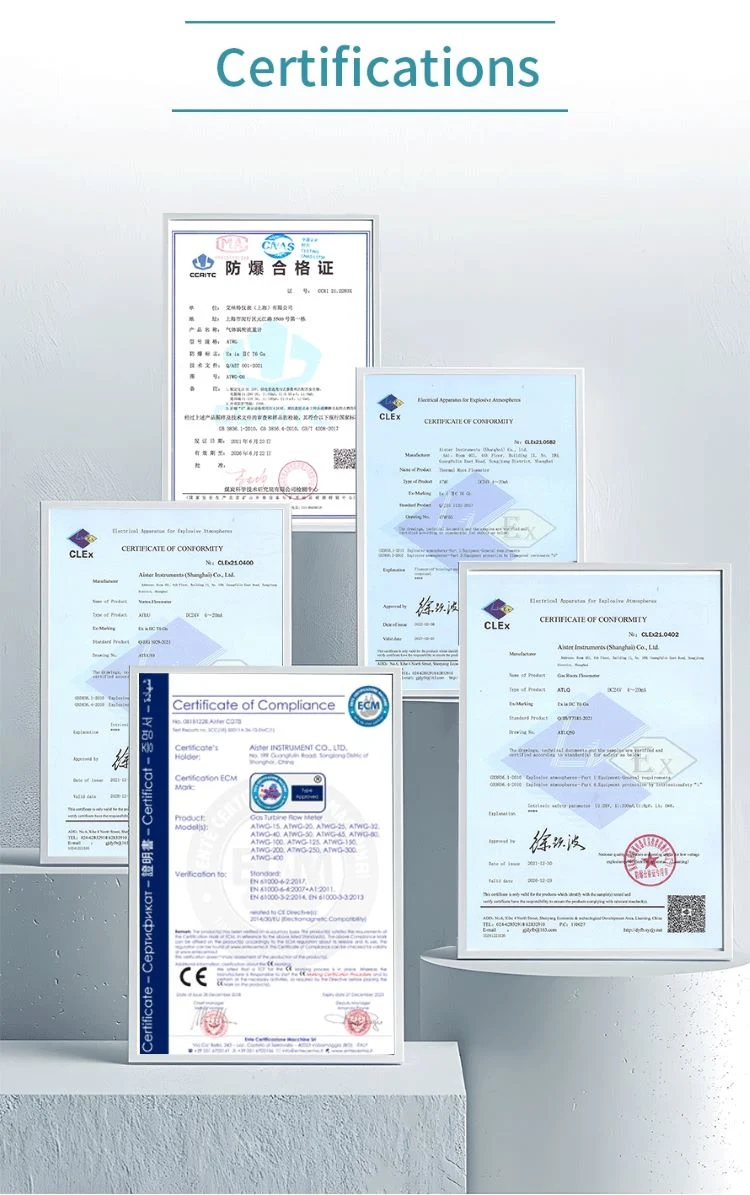

- Certifications

Basic Info.

Product Description

Gas Lobed Rotor (Roots) Flowmeter is a kind of gas monitoring and measuring instrument with high precision, high reliability and wide range. The intelligent Roots flowmeter is a new flowmeter that integrates flow, temperature, pressure sensors and intelligence on the basis of Roots flowmeter.

With the passage of gas, the pressure difference between the inlet and outlet of the gas meter acts on a pair of waist wheels connected together by a high-precision synchronous wheel, thereby driving the waist wheel to rotate, the gas filled with the metering room is quantitatively discharged, and then connected by a mechanical transmission and a calculator to achieve gas volume and data conversion.

It widely used in urban gas trade measurement, especially for organs, schools, enterprises and institutions, hotels, restaurants and other large gas users trade measurement. It can also be used for various industrial raw gas main metering, gas distribution station, main gas supply station and other occasions.

| Model | Flow Spec | Size (mm) | Flow Range (m³/h) | Start up flow (m³/h) | Max Pressure loss (KPa) |

| ATQL-25 | G16 | DN25 | 1-25 | 0.05 | 0.08 |

| ATQL-40 | G25 | DN40 | 1-40 | 0.05 | 0.08 |

| ATQL-50 | G25 | DN50 | 1-40 | 0.1 | 0.08 |

| G40 | 2-65 | 0.1 | 0.1 | ||

| G65 | 2-100 | 0.12 | 0.15 | ||

| ATQL-80 | G65 | DN80 | 2-100 | 0.12 | 0.15 |

| G100 | 2.5-160 | 0.1 | 0.15 | ||

| G160 | 3-250 | 0.1 | 0.18 | ||

| ATQL-100 | G160 | DN100 | 3-250 | 0.1 | 0.2 |

| G250 | 4-500 | 0.65 | 0.35 | ||

| ATQL-150 | G400 | DN150 | 8-650 | 0.76 | 0.46 |

| G650 | 15-1000 | 0.85 | 0.5 | ||

| ATQL-200 | G1600 | DN200 | 32-1600 | 0.95 | 0.6 |

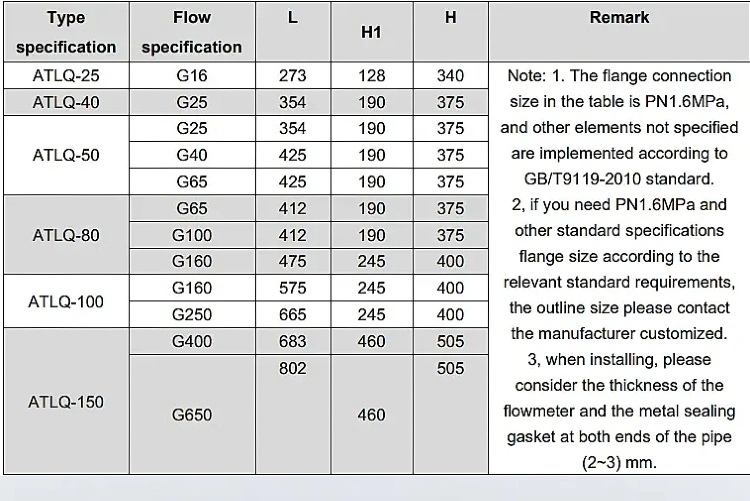

| Type specification | Flow specification | L | H1 | H | Remark |

| ATLQ-25 | G16 | 273 | 128 | 340 | Note: 1. The flange connection size in the table is PN1.6MPa, and other elements not specified are implemented according to GB/T9119-2010 standard. 2, if you need PN1.6MPa and other standard specifications flange size according to the relevant standard requirements, the outline size please contact the manufacturer customized. 3, when installing, please consider the thickness of the flowmeter and the metal sealing gasket at both ends of the pipe (2~3) mm. |

| ATLQ-40 | G25 | 354 | 190 | 375 | |

| ATLQ-50 | G25 | 354 | 190 | 375 | |

| G40 | 425 | 190 | 375 | ||

| G65 | 425 | 190 | 375 | ||

| ATLQ-80 | G65 | 412 | 190 | 375 | |

| G100 | 412 | 190 | 375 | ||

| G160 | 475 | 245 | 400 | ||

| ATLQ-100 | G160 | 575 | 245 | 400 | |

| G250 | 665 | 245 | 400 | ||

| ATLQ-150 | G400 | 683 | 460 | 505 | |

| G650 | 802 | 460 | 505 |

Installation Tips

- Before installation and use, the user should read this description in detail to ensure the correct installation and reasonable use of the flow meter, so as not to affect the normal operation and measurement accuracy;

- Before installing the flow meter, the outlet package should be removed, and granular impurities must be prevented from falling into the measuring room, such as anti-rust oil on the surface of the measuring room, which can be washed with gasoline or kerosene, and impurities in the pipeline should be strictly removed. A filter or filter should be installed upstream of the flow meter to prevent rust slag, welding slag and impurities from entering the measuring room;

- When the flow meter is installed, whether the outlet is vertical or horizontal, the rotor axis should be kept horizontal as far as possible. In order to prevent the rust slag and welding slag impurities in the newly installed pipeline from entering the flow meter, the user should first install the transition pipe on the installation position of the flow meter, vent for a period of time (about a week), ensure that there are no large particles of impurities, and then replace the flow meter;

- Install the flow meter to ensure that the center of the flow meter is aligned with the center of the pipeline, without misalignment, and that the flow meter is not affected by external forces (including axial and tangential).

| ATQL | Parameters | ××× | × | × | × | × | × | × |

| Size (mm) | DN25-DN200mm | |||||||

| Accuracy | 1.5% (standard) | 1 | ||||||

| 1.0% | 2 | |||||||

| Nominal Pressure | 1.0MPa | 1 | ||||||

| 1.6MPa | 2 | |||||||

| Others | 3 | |||||||

| Body Material | Aluminum Alloy | A | ||||||

| Stainless Steel | S | |||||||

| Output/ Communication | Pulse | 1 | ||||||

| Pulse+4~20mA | 3 | |||||||

| Pulse+4~20mA+RS485 | 4 | |||||||

| Power Supply | Battery Powered | 1 | ||||||

| Battery Powered + External Power DC24V | 2 | |||||||

| Ex-proof | With | 1 | ||||||

| Without | 2 | |||||||

| Installation | Horizontal | H | ||||||

| Vertical | V | |||||||