- Overview

- Product Description

- Detailed Photos

- Our Advantages

- Certifications

- Packaging & Shipping

- Company Profile

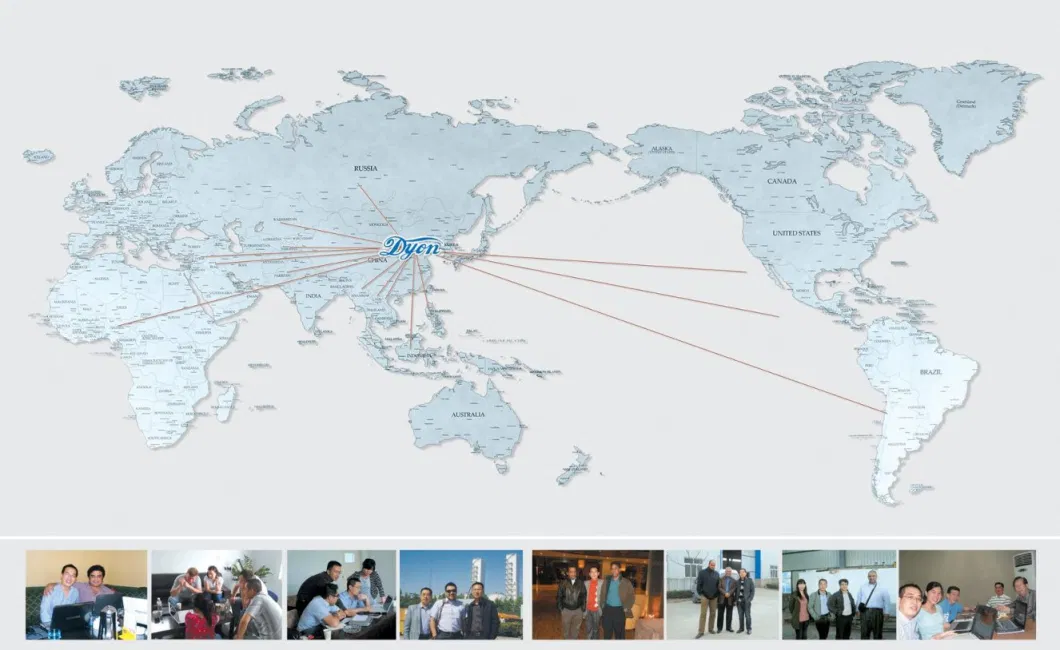

- Sales And Service Network

- FAQ

Basic Info.

Product Description

Differ from Pressure swing adsorption process (PSA) process, we adopt Cryogenic distillation process for making the air separation plant.

With this process, pure gases can be separated from air by first cooling it until it liquefies, then selectively distilling the components at their various boiling temperatures. It can produce high purity gaseous and liquid product.

The air separation plant is mainly composed of seven parts: air compression system, air pre-cooling system, air purification system,Turbine expander, Cold box, liquid pump, and product filling station.

| Air compressor The inlet air will be compressed into the pressure as per process required. It is sprayed-oil screw compressor, box-body construction, it have low noise, whole machine gather gas, lubricate, water, electric, cooling and instrument to one, realize machine and electric become one body. | Pre-cooling unit The outlet temperature of compressed air is around 40ºC which is too high for the down-stream molecular sieves high efficiency operation, in order to increase the performance of the molecular sieves, a pre-cooling unit is required. | Purifier Remaining contaminants in the process air such as moisture, carbon dioxide, acetylene (and etc.) shall be removed before enters into the main heat exchanger, a molecular sieves system is adopted. |

- All unit machines are skid-mounted construction, connected by fixed-size short pipe, it's not complicated to install.

- Adopt liquid oxygen pump inner-compress technology, could produce high-quality oxygen, which can be used both for medical and industrial filed.

- Complete set plant runs stablly, and it's easy to operate, convenient to maintenance, and we supply a two-year spare parts freely.

- Set four-stage pipeline oil-removing filter with imported filter element. Each filter element shall be replaced with monitor to remind users to replace the filter element regularly, preventing the oil and water in the air from entering the purifier and fractionating tower.

- Design and manufacture of the external cleaning tower system of the fractionating tower, no need open to clean the oil in the fractionating tower, avoiding the trouble of removing and reloading perlite, cutting and welding aluminum pipes and leak detection.

- All the fractionating tower is filled with waterproof pearlite (perlite), which ensures the start-up time of normal oxygen production due to its excellent cooling effect.

All equipments are packed as required as transportation standard.

All equipments are packed as required as transportation standard.

Q1: What is your company specialized in?

-We're a professional engaged in air separation plant, dissolved acetylene plant, chemical tail gas recycling equipment, food grade CO2 equipment, liquefied natural gas equipment, design, research and development, manufacture and after-sales service as one of technological innovation-oriented enterprises.

Q2: Are you a manufacturing factory or trading company?

-We are professional manufacturer.

Q3: Where is your factory located?

-We're located in Shenglong industrial park, Handan city, Heibei province of China.

Q4: Can I come to your factory to observe machine running? Can you arrange driver to pick me up?

-Yes, we welcome you to visit our factory and if you come, we'll arrange driver to pick you in the train station or airport.

Q5: Where do you sell your product/what is your major market?

-Our product is sold both at home and abroad.

Q6: Why should we choose you over others?

-With long-term technical research and continuous innovation, combined with market demand, our equipment has been continuously optimized both in design and manufacturer, which makes our equipment sell well all over the world.

Q7: What do you think is your biggest advantage?

-Our engineers is engaged in the field of cryogenic and chemical products' technical research and development and manufacturing for many years. Our plant adopt advanced technology, have low consumption, high efficiency, easy operation etc. advantages, could design according to User special requirement.

Q8: How long have you been in this business?

-We've been in this business more than 20 years.

Contact information