- Overview

- Product Description

- Product Parameters

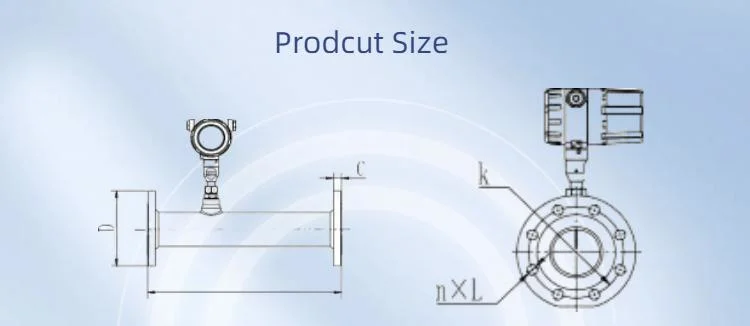

- Products Size

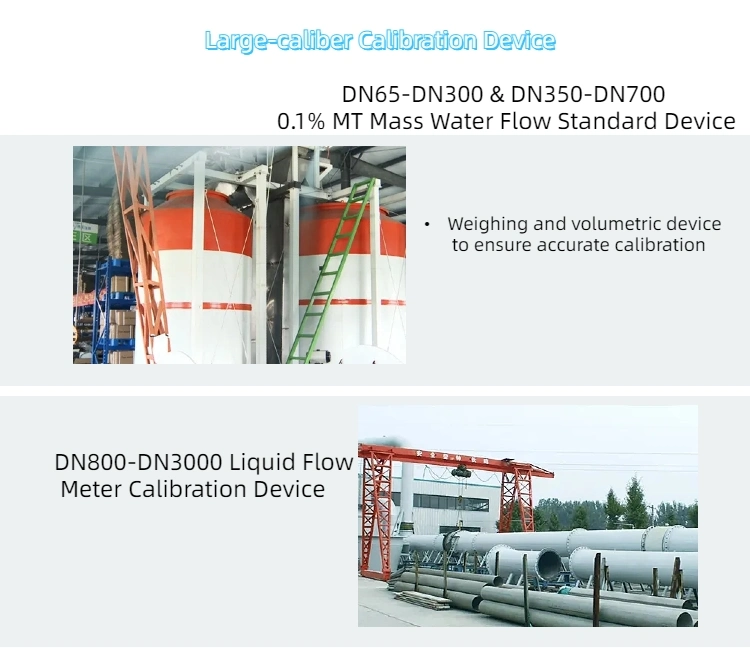

- Why Choose Us

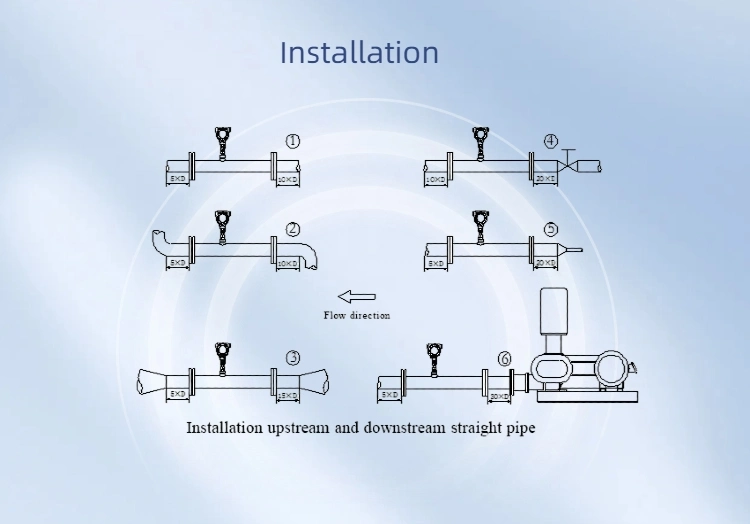

- Installation Instructions

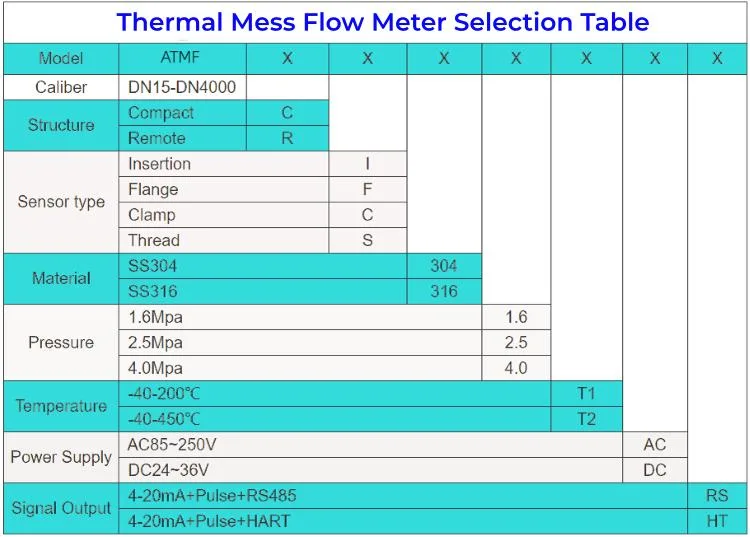

- Model Selection

- Certifications

Basic Info.

Product Description

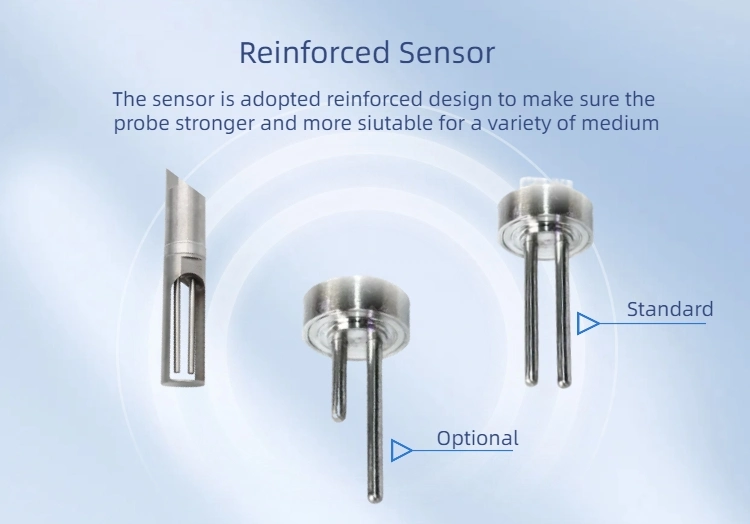

The thermal mass flowmeter is an instrument for measuring gas flow by using the principle of thermal diffusion. The sensor consists of two reference thermal resistors (RTDS). One is the speed sensor RH, and the other is the temperature sensor RMG, which measures the temperature change of the gas. When the two RTDS are placed in the measured gas, one sensor RH is heated and the other sensor RMG is used to sense the measured gas temperature. As the gas flow rate increases, the airflow carries away more heat, and the temperature of the sensor RH drops.

The Insertion thermal gas mass flowmeter can be installed and maintained online. The installation process is to first weld a base with external threads on the outer wall of the pipeline, install a 1-inch stainless steel ball valve on the base, and then use a special tool to drill a hole with a diameter of 22mm, remove the special tool after the hole is drilled, and then install the sensor on the valve and insert the sensor into the center of the pipe (the insertion position of the sensor has been determined before the factory). Insertion thermal gas mass flowmeter suitable for pipe diameter: DN32 ~ 6000mm.

| Performance | Technical parameter | |

| Structural form | plug-in | pipe |

| Measuring medium | All gases (except acetylene) | |

| Diameter range | Caliber DN32 or higher | DN10~DN200mm |

| Velocity range | 0.1~120Nm/s | |

| Precision | ±1~2.5% | |

| Operating temperature | Sensor:-40ºC~+120ºC convertor:-20ºC~+45ºC | |

| Working pressure | Medium pressure≤2.5Mpa | Medium pressure:4.0Mpa |

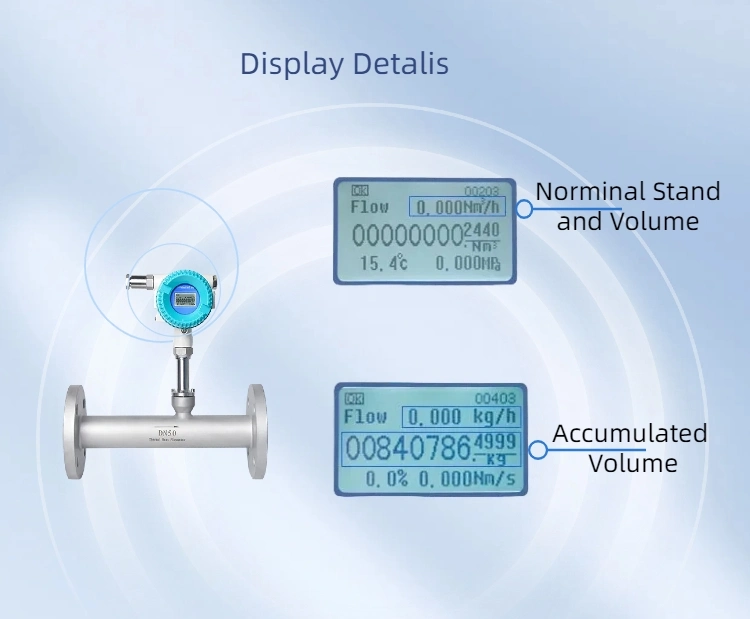

| Power supply | DC24V or AC220V≤18W | |

| Response speed | 1s | |

| Output signal | 4-20mA (Photoelectric isolation, large load 500Ω),pulse,RS-485 (photoelectric isolation),HART agreement | |

| Alarm | 1-2 relay normally open contact,10A/220V/AC,*/30V/DC | |

| Type of supply | Separate structure, integrated structure | |

| Pipe material | Carbon steel, stainless steel | |

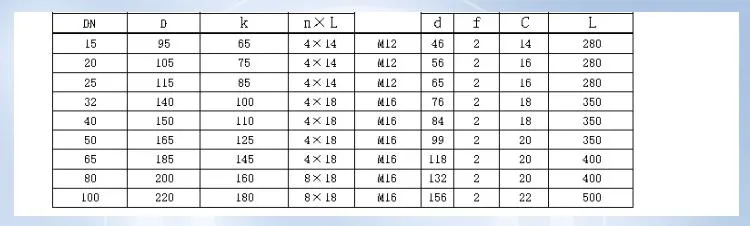

| Local display | Four lines of Chinese liquid crystal display | |

| Display content | Mass flow, standard volume flow, cumulative flow, standard time, cumulative running time, standard flow rate, etc | |

| Protection degree | IP65 | |

| Sensor material | Stainless steel | Stainless steel, carbon steel |

Installation Tips

- Verify the actual internal diameters and wall thickness of the pipe before installing the Insertion thermal mass flowmeter.

- First of all, 25 holes are opened in the pipeline, and the base is welded at the opening hole, and then the rest of the thermal mass flowmeter is loaded into the special ball valve together, and the depth to be inserted is calculated according to the actual pipe diameter and wall thickness. This step can be inserted to approximate size and hand tighten the nut.

- Turn the sensor connecting rod so that the marked arrow is in the same direction as the medium flow.

- According to the data measured in the field, convert the corresponding scale on the sensor connection rod, and lock the nut.

- If you are horizontally installed, the display of this instrument can be flexibly installed at 90°, 180°, 270° to meet your actual needs.

Mounting base

Do not weld in an explosive environment.

The environment with special requirements for welding should be operated in accordance with the relevant requirements.

The base is divided into two types according to the different installation methods: welding and clamping. When installing, the base should be located at the apex of the section direction of the pipeline, and the axis of the base through the hole is perpendicular to the axis of the pipeline. The effect diagram of the welded base has been installed (the welding position has been treated with rust prevention).

Installing ball valves

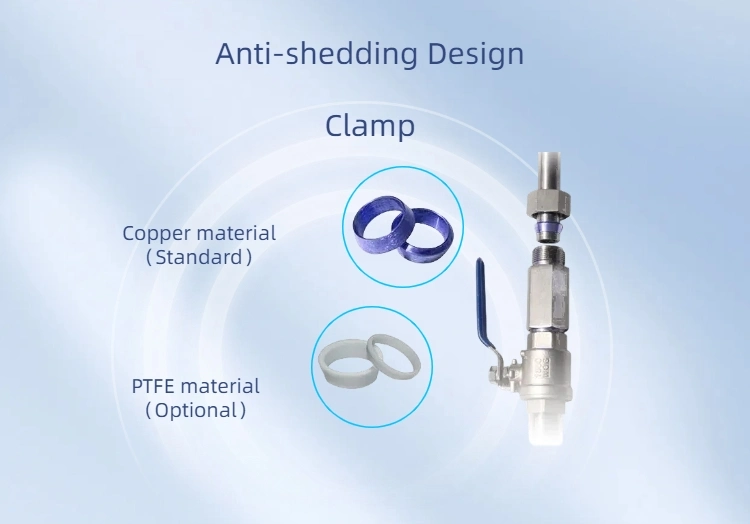

Secure the stainless steel valve to the base. Use a gasket on the crimped contact surface (nylon material is used when the medium temperature is below 100 ° C, copper material is used when the medium temperature is above 100 ° C).

punching

Before drilling holes, check the site environment carefully to ensure the safety of operations.

Close the valve in time after drilling to avoid air leakage.

In the case that online drilling is allowed, the opening tool of Sen Ling Instrument Co.Ltd. can be used to realize online installation without stopping production. See related instructions for the use of the tool. When stopping drilling, a variety of methods can be used to punch holes, to ensure that the axis of the hole and the base of the hole axis concentric. If the hole is opened by gas cutting, the drilling operation should be arranged before the base welding.

A: it depends on the quantity. Normally it's about a week to two weeks.

Q: How to get quotation?

A: Please tell us the pipe diameter, measuring medium, flow rate, temperature, pressure, connection type and accuracy of the product you need, we will choose the most suitable product for you.

Q:can i design our own logo or color ?

A:sure ! we are glad to help you.

Q:Can I place a small order for the first time?

A:YES. This shows your recognition of us, I believe we will have longer-term cooperation.