- Overview

- Features

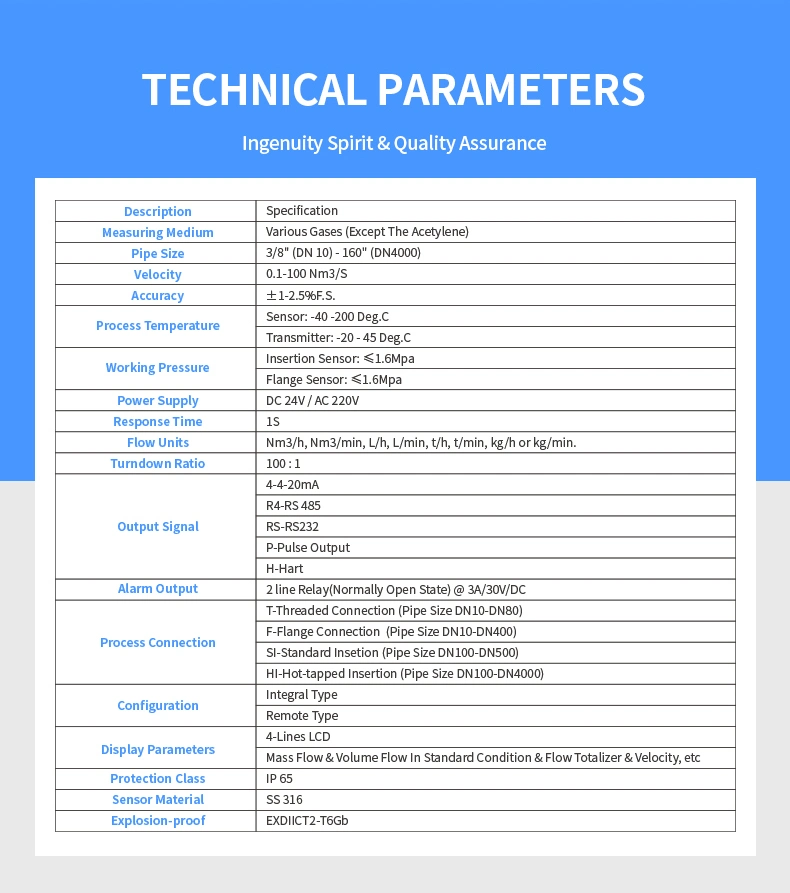

- Product Parameters

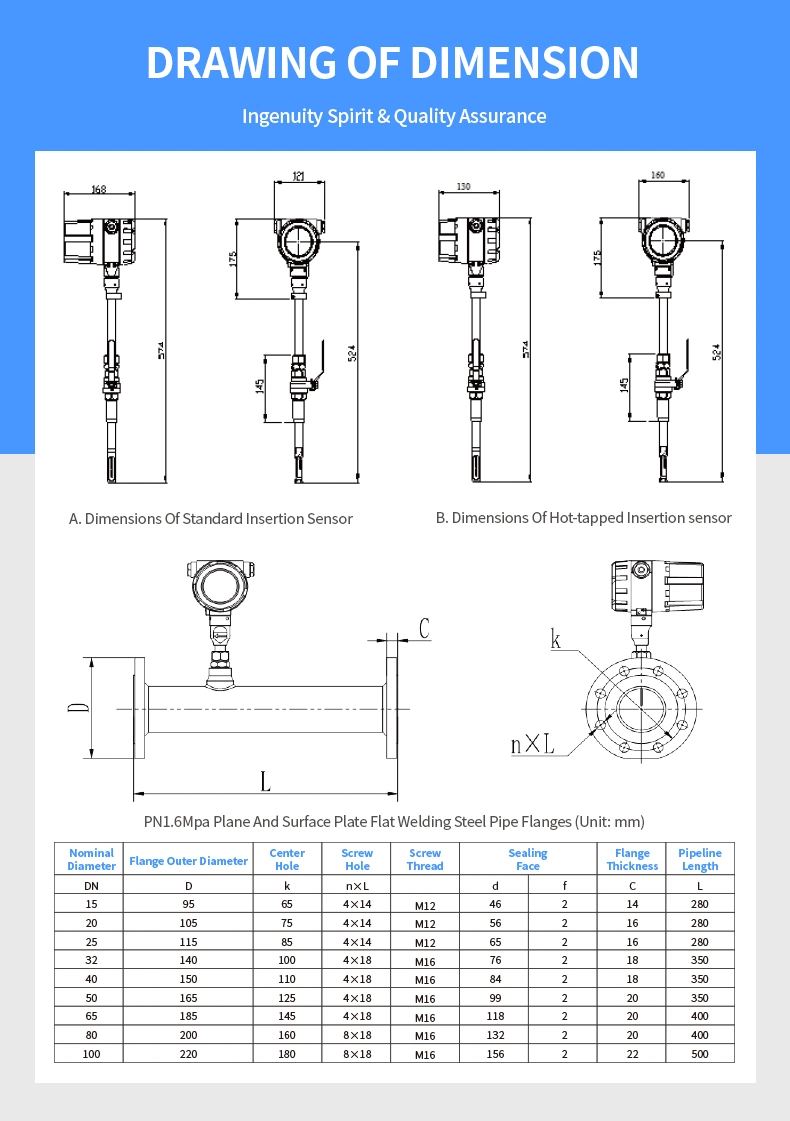

- Outline Dimension

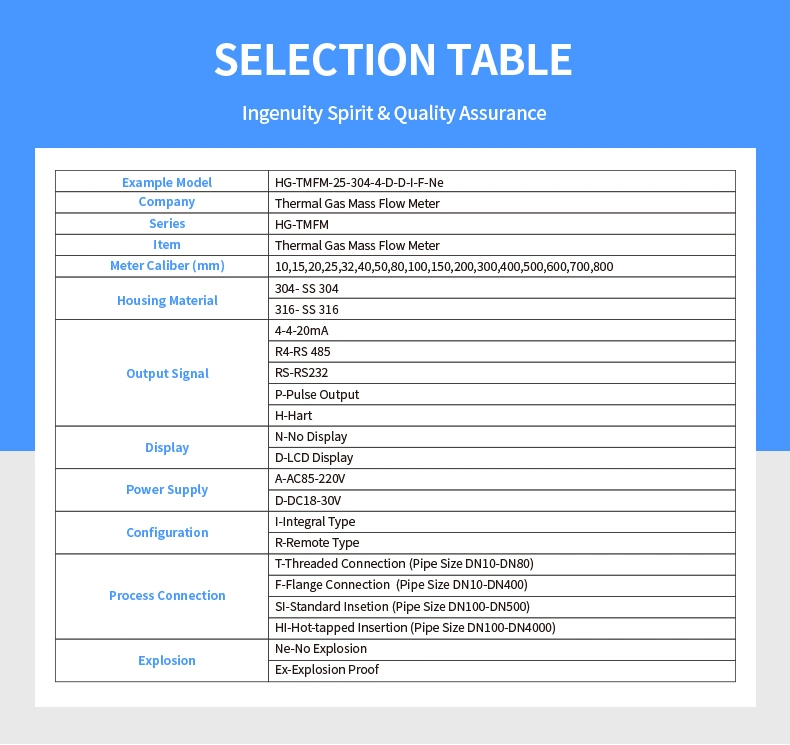

- Selection Table

- Company Profile

Basic Info.

Model NO.

HG-TMFM Thermal Gas Mass Flow Meter

Main Application

Nature Gas, Corrosive Liquid/Gas, Various Gases (Except The Acetylene)

Size

3/8" (DN 10) - 160" (DN4000)

Sensor

Thread / Flange / Clamp on

Application

Industrial Production

Type

Thermal Gas Mass Flow Meter

Measuring Media

Gas

Measuring Principle

Thermal Gas Mass Flow Meter

Measurement Object

Closed Pipeline

Certification

JIS, DIN, ANS, GB, CE, RoHS, ISO

Line Size

3/8" (DN 10) - 160" (DN4000)

Working Temperature

Sensor: -40 -200 Deg.C Transmitter: -20 - 45 Deg.C

Working Pressure

1.6MPa

Flow Units

Nm3/H, Nm3/Min, L/H, L/Min, T/H, T/Min, Kg/H or Kg

Turndown Ratio

100 : 1

Sensor Material

Ss 316L

Power Supply

DC12-24V, 3.6V Lithium Battery

Protection Level

IP 65 (Integrated Type)

Ambient Temperature

-20 - 55 Deg.C

Ambient Pressure

86 -106 Kpa

Signal Output

P-Pulse, 4-20mA, RS 485, Hart

Signal Transmission Distance

1, 000m

Display

4-Lines LCD

Connection

Threaded Connection, Flange Connection, Standard I

Explosion-Proof

Exdiict2-T6GB

Transport Package

10kg

Specification

28*28*40cm

Trademark

Siko Instruments

Origin

China

HS Code

9026100000

Production Capacity

999 Units / Weeks

Packaging & Delivery

Package Size

40.00cm * 25.00cm * 25.00cm

Package Gross Weight

10.000kg

Product Description

Medical Application DN80 Pipeline Thermal Mass Flow Meter For Nitrogen Gas

The Siko Instruments HG-TMFM Thermal Gas Mass Flow Meter are thermal dispersion type, it utilizing the constant temperature difference methods of measuring ga mass flow rate. It contains two reference grade platinum RTD sensors clad in protective SS 316 sheath. Its' features include direct mass flow measurement for gases, wide range-ability, low pressure drop, excellent low end sensitivity, and no moving parts.

| 01 | Direct mass flow measurement of gas with actual gas calibration. |

| 02 | Wide measuring range 0.5 Mm3/s - 100 Nm/s for gas. |

| 03. | No need temperature and pressure compensation with accurate measurement. |

| 04. | No moving parts with good vibration resistance and long service life to provide user easy installation and free from maintenance. |

| 05. | Opto-isolated outputs with digital design configuring with RS 485 or Hart interface to realize factory automation and integration. |

| 06. | OLED display with rate, total, mass flow, velocity etc display |

| 07. | Tracking of overall gas consumption over a turndown ratio of at least 100:1 |

| 08. | Low pressure drop, with excellent low end sensitivity |