- Overview

- Product Description

- Product Parameters

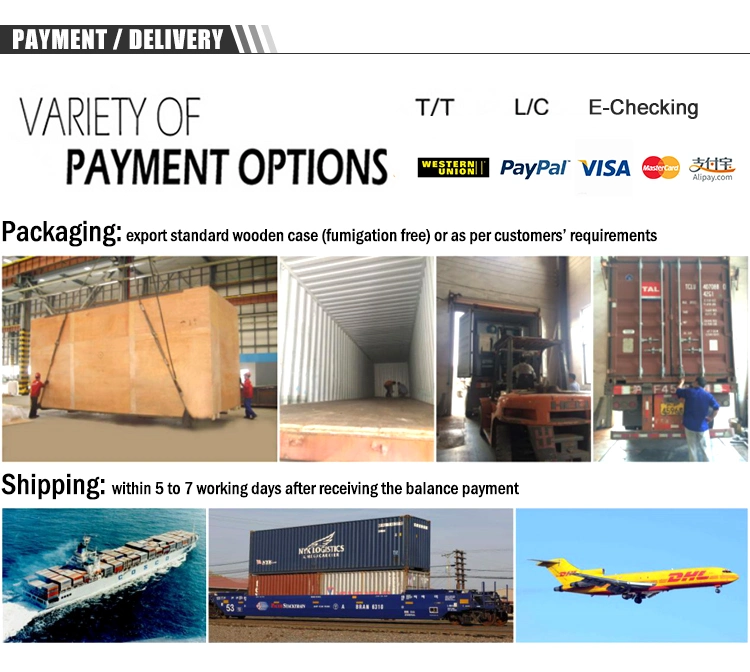

- Packaging & Shipping

- Our Advantages

Basic Info.

Product Description

Egg Powder Centrifugal Atomizer Spray Dryer/Egg Powder Extracting Spray Drying Machine /Egg Powder Water Evaporating Dehydrator

Introduction

The spray dryer is one of the continuous atmospheric dryers. The liquid material is sprayed with a special device to form a mist, and is dried in contact with hot air. For the drying of some heat-sensitive liquids, suspensions and viscous liquids, such as milk, eggs, tannins and drugs. Also used for drying fuels, intermediates, soap powder and inorganic salts.

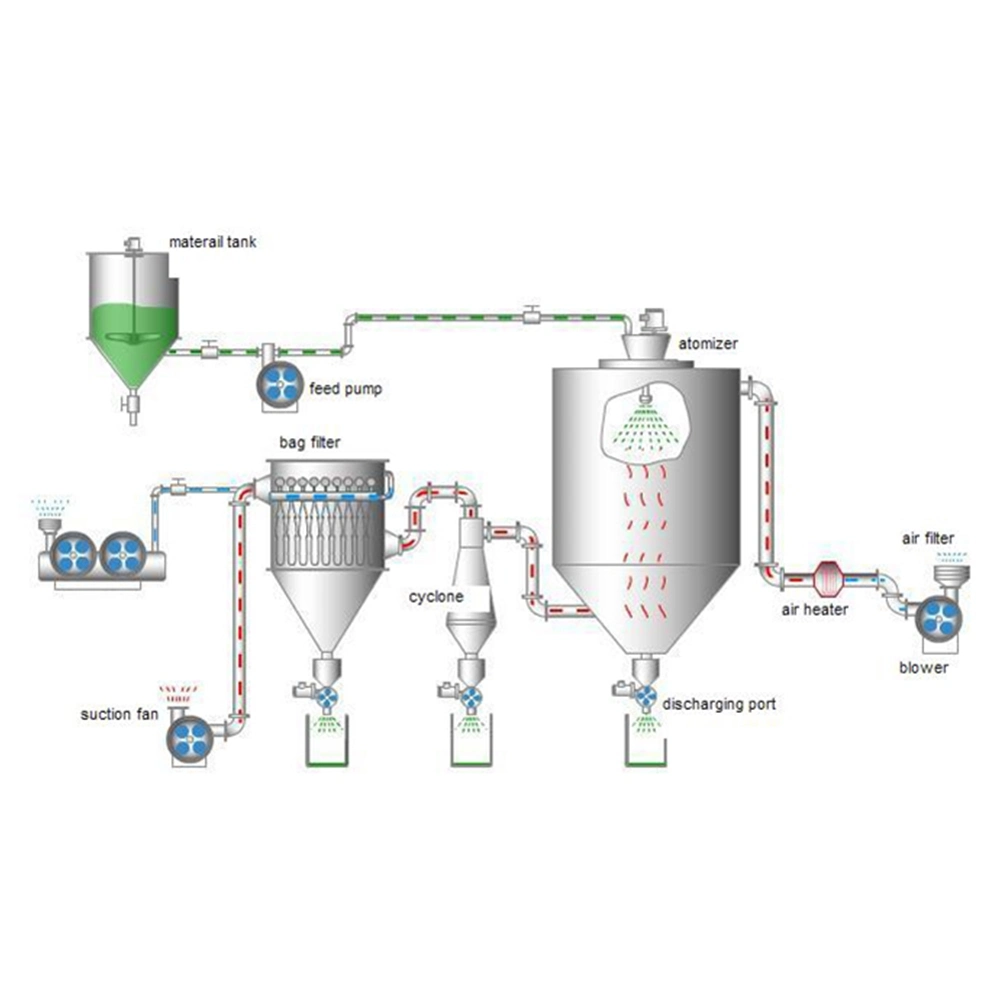

Working Principle

The air is filtered and heated into the top of the dryer air distributor, hot air into the spiral evenly into the drying chamber. The material liquid is sprayed into a fine atomized liquid droplet through the high-speed centrifugal nebulizer at the top of the tower body, and can be contacted with the hot air in a very short time and can be dried into finished products. The finished product is continuously discharged from the bottom of the drying tower and the cyclone, and the exhaust gas is drained by the draft fan.

| Item Model | LPG-5 | LPG-25 | LPG-50 | LPG-150 | LPG-200~2000 |

| Inlet temp. ºC | 140~350 | 140~350 | 140~350 | 140~350 | 140~350 |

| Outlet temp. ºC | 80~90 | 80~90 | 80~90 | 80~90 | 80~90 |

| Max. water evaporation kg/h | 5 | 25 | 50 | 150 | 200~2000 |

| Transmission form of centrifugal atomizer | Compressed air transmission | Mechanical transmission | Mechanical transmission | Mechanical transmission | Mechanical transmission |

| Maximum speed (r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Diameter of atomizer (mm) | 50 | 120 | 120 | 150 | 180-240 |

| Heat source | Electricity | Electricity, steam, natural gas, LPG | |||

| Max. power of electric heater (kw) | 9 | 36 | 72 | 99 | |

| Overall dimensions (LWH) (m) | 1.8*0.93*2.2 | 3*2.7*4.26 | 3.5*3.5*4.8 | 5.5*4*7 | |

| Dry powder recovery rate (%) | ≥95% | ||||

| Note: The amount of water evaporation is related to the characteristics of the material and the temperature of the hot inlet and outlet. | |||||

Product Features

High speed drying:the surface area of liquid material is greatly increased after atomization, achieving instantaneous evaporation of 95% -98% water in the hot air flow, drying time only takes a few seconds, especially for heat-sensitive materials

Products achieve good uniformity, mobility and solubility, and also achieve purity, good quality. The production process is simplified and the operation control is convenient. For liquid materials with the moisture content of 40-60% (special materials up to 90%) can be dried into powder products just with one time, do not need grinding and screening after drying, reduce production processes and improve product purity. The product size, bulk density, moisture, in a certain range can be adjusted by changing operating conditions, control and management are very convenient.

The air is filtered and heated into the top air distributor of the dryer, and the hot air enters the drying chamber evenly in a spiral fashion. The material liquid is sprayed into a fine atomized liquid droplet through the high-speed centrifugal nebulizer at the top of the tower body, and can be contacted with the hot air in a very short time and can be dried into finished products. The finished product is continuously discharged from the bottom of the drying tower and the cyclone, and the exhaust gas is drained by the draft fan.

One-year warranty, 24-hour hot-line service, complete components & parts are ready for supply anytime.

The company has a full-time after-sales service team, they are from the manufacturing staff who understand the operation of the equipment very well, they will solve all problems encountered by customers, and provide you with timely maintenance and use recommendations.