Basic Info.

Model NO.

HVAF

Porosity

Between 0.1 and 0.3 Percent

High Deposition Efficiency

5-30 M,15-45 M (Hvof Mode)

Powder Feeding Efficiency

0.26kg/H

Fuel

Propane and Compressed Air

Transport Package

Wood

Specification

powder feeder, spray gun and control cabinet

Trademark

Lijia

Origin

Zhengzhou, China

HS Code

8424899990

Production Capacity

100/Year

Product Description

| Component | Characteristic | Parameter |

| HVAF Control cabinet | 1. Imported core parts, full closed-loop system, Mitsubishi high performance PLC control 2. Solid design, pressure sensor and solenoid valve all imported from Europe and America, the quality is the same as the European and American equipment. 3. Touch screen operation, intelligent automatic operation; 4. Process parameters are clear on the touch screen panel; 5. One-key operation can realize automatic and real-time detection of spraying process, and multiple alarm prompts can make immediate response to system failure. | 1. Program control: full closed-loop PLC control 2. Interface control: 15-inch touch screen 3. Flow control: mass flow controller + electric pressure regulating valve 4. Propane pressure: 1.0mpa 5. Air pressure: 1.1Mpa 6. Carrier gas pressure: 1.0mpa 7. Propane flow rate: 0~50kg/h 8. Air flow rate: 400-600m /h 9. Carrier gas flow: 0~100L/min 10. Main parts producing areas: America, Japan and Italy |

| Component | Characteristic | Parameter |

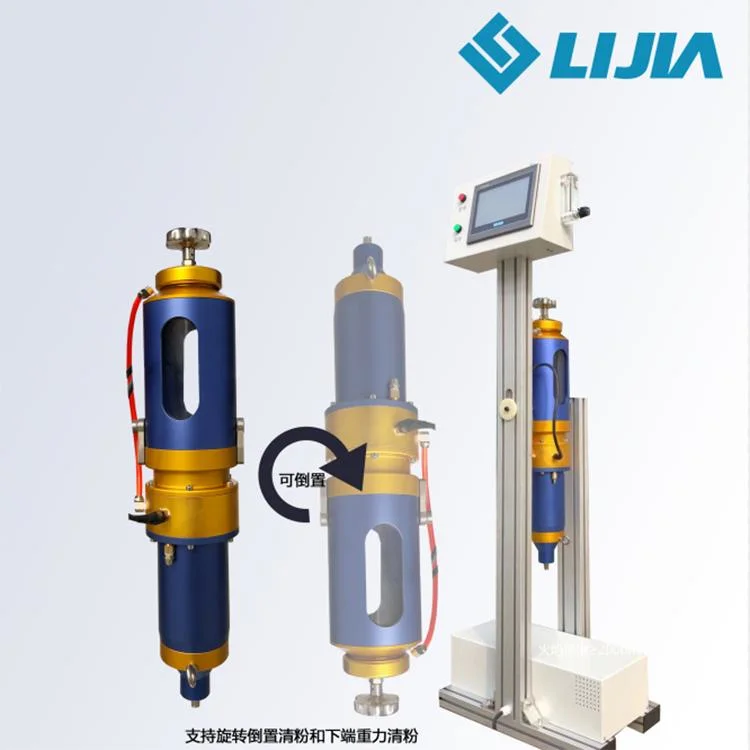

| E-2000 Powder feeder | 1. The powder feeder is a high-precision powder feeding mechanism based on the principle of toothed dial with vibration structure and gravity falling, with uniform powder output and wide particle size range. 2. After the top cover is sealed, the powder condition in the powder cylinder can be clearly seen through the visual transparent observation window on the powder cylinder. 3. Nitrogen or argon with small flow is used as powder gas. The powder is rotated to the powder outlet along with the powder tray at the bottom and enters into the spray gun together with the powder gas. 4. Adopting the latest international turnover structure, it is convenient to clean the powder, which can be discharged from the lower mouth, or can be poured from the barrel body. | 1. Powder feeding: toothed dial 2. Cleaning method: barrel body flip 3. Volume of powder storage tube :2L 4. Powder feed gas: nitrogen 5. Powder feeding air pressure: 0.15-1.2mpa 6. Powder feeding speed :0~500g/min 7. Powder feeding accuracy :±1% 8. Powder size :1~150 m |

| Item | Coating properties (WC as an example) | Other features (WC as an example) |

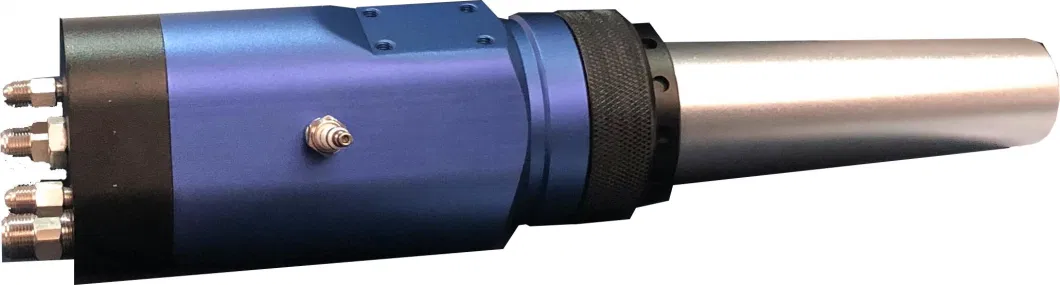

| LA2 supersonic flamethrower | 1. Hardness: 1050-1400HV0.3 2. Porosity: less than 0.5% 3. The coating generates residual compressive stress 4. The oxide content in the coating can be ignored | 1. Powder size: -30+5 m, -30+10 m 2. Particle velocity: about 935m/s 3. Deposition rate: 40-55% 4.Maximum spraying rate: 30kg/h |

| LA3 supersonic flamethrower | 1. Hardness:1050-1600HV0.3 2. Porosity: less than 0.5% 3. The coating generates residual compressive stress 4. The oxide content in the coating can be ignored | 1. Powder size: -30+5 m, -30+10 m, -40+15 m 2. Particle velocity: about 935m/s 3. Deposition rate: 40-62% 4. Maximum spraying rate: 35kg/h |

HA-2000 has many functions and features, and its advantages are mainly reflected in the following aspects:

1) Touch screen operation, the design structure of the equipment adopts full closed-loop automatic control structure, the gas is all controlled by pressure sensors imported from the United States and pressure regulating valves imported from Japan, the pressure can be monitored in real time and automatically reach the set value of the process.

2) The fuel is propane and the combustion-supporting agent is air, which is the safest combustion mode among the gas models in the market at present;

3) The structure of the spray gun is designed according to the principle of the rocket generator. The flame flow speed reaches over 2000m/s, with large output power and stepless adjustment;

4) The spray gun adopts axial center powder feeding. This new injection method makes the powder dissolve well and distribute evenly in the whole flame, which improves the coverage efficiency and coating quality;

5) It has the function of process recipe storage and invocation. Parameters can be added, modified and saved.

6) The system fuel adopts full closed-loop design, modular design, high-performance PLC control, safe and simple operation;

7) The coating produced has excellent performance with low porosity less than 1% (average porosity less than 0.5%) and high spray efficiency (up to 30KG powder per hour).