Basic Info.

Model NO.

HLTO2-30

Condition

New

Certification

RoHS, UR, ISO, CE, CCC

Oxygen Capacity

1~200lm3/H

Oxygen Purity

91-96%

Oxygen Pressure

0~0.5MPa

Dew Point

-40oc

Transport Package

Wooden Case Packing

Specification

Certificate: ISO9001: 2008

Trademark

HUILIN

Origin

Guangdong

HS Code

8419601900

Production Capacity

10sets/Month

Product Description

Oxygen Generator

1)high purity

2)exellent energy-saving

3)smoothly running, long-life

4)automatic operating

Principles

N2 and O2 all have a quadrupole, for the reason that the quadrupole of N2 is bigger than the quadrupole of O2, the adsorption capacity by molecular sieve to N2 is stronger than O2. When the compressed air in certain pressure flow through adsorption bed formed by molecular sieve, the N2 gas is absorbed and O2 is obtained by separation.

The main part of O2 generator is two towers filled with molecular sieve, when the compressed air get into adsorption tower, the N2 is absorbed by molecular sieve, O2 is produced from the export terminal. When one tower produces O2, another tower release the N2 by reducing the pressure to get the renewable desorption of carbon molecular sieve. Two towers alternate adsorption and regeneration to output O2 continuously.

Technical classification

According to the different pressure of adsorption and desorption, we usually divide pressure swing adsorption system into three different technology(PSA, VPSA, OPSA), users could choose the most suitable technology based on working conditions and requirements to achieve the purpose of reducing energy consumption.

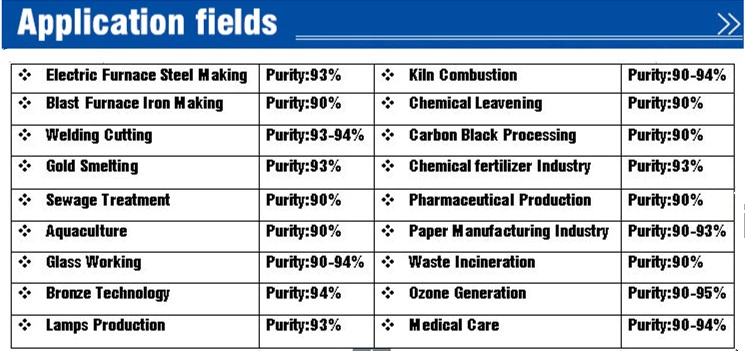

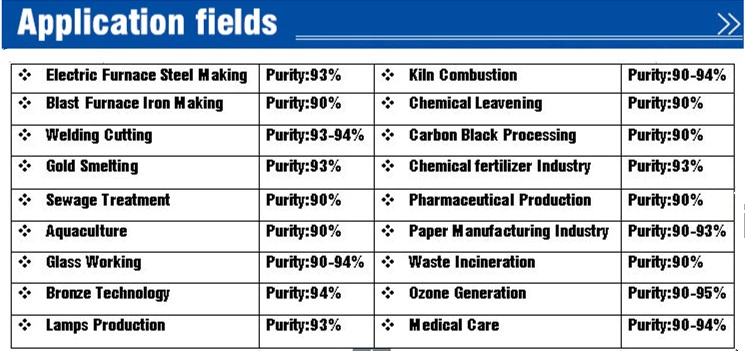

Oxygen generator applications

Paper and Pulp industries

Glass industries

Metallurgical industries

Chemical industries

Water and Wastewater treatment

Fish farming

PSA

VPSA

1)high purity

2)exellent energy-saving

3)smoothly running, long-life

4)automatic operating

Principles

N2 and O2 all have a quadrupole, for the reason that the quadrupole of N2 is bigger than the quadrupole of O2, the adsorption capacity by molecular sieve to N2 is stronger than O2. When the compressed air in certain pressure flow through adsorption bed formed by molecular sieve, the N2 gas is absorbed and O2 is obtained by separation.

The main part of O2 generator is two towers filled with molecular sieve, when the compressed air get into adsorption tower, the N2 is absorbed by molecular sieve, O2 is produced from the export terminal. When one tower produces O2, another tower release the N2 by reducing the pressure to get the renewable desorption of carbon molecular sieve. Two towers alternate adsorption and regeneration to output O2 continuously.

Technical classification

According to the different pressure of adsorption and desorption, we usually divide pressure swing adsorption system into three different technology(PSA, VPSA, OPSA), users could choose the most suitable technology based on working conditions and requirements to achieve the purpose of reducing energy consumption.

Oxygen generator applications

Paper and Pulp industries

Glass industries

Metallurgical industries

Chemical industries

Water and Wastewater treatment

Fish farming

Model Type | PSA | VPSA | VSA |

Production Flow (Nm3/h) | 3~120 | 150~2000 | 2000~10000 |

O2 Purity (%) | 65%~95% | 80%~93% | 80%~93% |

Pressure of Export | 0.2MPa~0.3MPa | 18KPa~30KPa | 10KPa~15KPa |

Dew Point of Standard atmosphere (°c) | -45 | -40 | -40 |

Energy Consumption | 0.4~0.52 KWh/Nm 3 O2 | 0.35~0.45 KWh/Nm 3 O2 | 0.30~0.42KWh/Nm 3 O2 |

PSA

Model | O2 Output (N 3 /h) | Power (kw/h) | Dimension(mm) | (mm) | Purity (%) | |||

L | W | H | Inlet | Outlet | ||||

WG-OPSA-5 | 5 | 0.11 | 1500 | 1400 | 1600 | DN25 | DN15 | 91~95 |

WG-OPSA-10 | 10 | 0.11 | 1700 | 1550 | 1900 | DN32 | DN15 | |

WG-OPSA-15 | 15 | 0.11 | 1900 | 1100 | 2200 | DN40 | DN25 | |

WG-OPSA-20 | 20 | 0.11 | 2100 | 1250 | 2340 | DN50 | DN25 | |

WG-OPSA-30 | 30 | 0.11 | 2300 | 1450 | 2550 | DN50 | DN25 | |

WG-OPSA-40 | 40 | 0.11 | 2350 | 1500 | 2580 | DN65 | DN25 | |

WG-OPSA-50 | 50 | 0.11 | 2350 | 2500 | 2580 | DN65 | DN40 | |

WG-OPSA-80 | 80 | 0.11 | 2300 | 2580 | 2580 | DN100 | DN50 | |

WG-OPSA-100 | 100 | 0.11 | 2350 | 2780 | 2580 | DN125 | DN50 | |

WG-OPSA-150 | 150 | 0.11 | 2700 | 3400 | 3100 | DN150 | DN65 | |

VPSA

Model | O2 Output (N 3 /h) | Power (kw/h) | Cooling Water (ton/h) | Purity(%) |

WG-OPSAV-200 | 200 | 170 | 5 | 91~95 |

WG-OPSAV-300 | 300 | 240 | 8.2 | |

WG-OPSAV-500 | 500 | 325 | 11.2 | |

WG-OPSAV-1000 | 1000 | 600 | 20 | |

WG-OPSAV-3000 | 3000 | 1760 | 32 |