Basic Info.

Model NO.

PB-15

Outlet Pressure

0~5bar Adjustable

Size

6000*2300*2300mm

Dew Point

-40 to -60 Centigrade

Transport Package

Wooden Case

Specification

15Nm3/h

Trademark

PowerBuilder

Origin

China

HS Code

8419601900

Production Capacity

1000

Product Description

15Nm3/H Containerized Medical and Industrial Use Psa Oxygen Generator with Filling System(CE,ISO9001)

Product Image

1.Description for containerized oxygen generator

Containerized oxygen generator is consisted of the screw air compressor, air dryer, filters, buffer tanks, oxygen generator, electricity control system and the optional oxygen cylinder filling station. The complete system is installed and tested at factory, delivery to customer's turn-key project.

PB containerized oxygen generator is removable, and makes the onsite installation and operation very easy. It can also save the cost for the decoration cost of the machine room.

2. Main Features for easy installation oxygen generator supplier price

1.Turn-ey project and removable, easy for installation and operation;

2.Small and easy machine room;

3.Heat and sound insulation treatment;

4.Smart monitor and control system, support for remote data transfer.

3. Containerized PB PSA Oxygen Generator Models

| Range of the Containerized PSA Oxygen Generator | |||||||

| Model | O2 Flow (Nm3/h) | O2 Flow (LPM) | Equivalent cylinder-7m3(per day Nos) | Power With booster(Kw) | Power Without HPBC(Kw) | Purity | Loading |

| PB-5C | 5 | 83 | 17 | 13 | 9 | 93%±3% | 2100*1560*2000mm |

| PB-10C | 10 | 167 | 34 | 22 | 16.5 | 93%±3% | 20GP |

| PB-15C | 15 | 250 | 51 | 28 | 20.5 | 93%±3% | 20GP |

| PB-20C | 20 | 333 | 68 | 43 | 32 | 93%±3% | 20HQ |

| PB-25C | 25 | 417 | 85 | 43 | 32 | 93%±3% | 20HQ |

| PB-30C | 30 | 500 | 102 | 55 | 40 | 93%±3% | 40HQ |

| PB-40C | 40 | 667 | 136 | 63 | 48 | 93%±3% | 40HQ |

| PB-50C | 50 | 833 | 170 | 76 | 57.5 | 93%±3% | 40HQ |

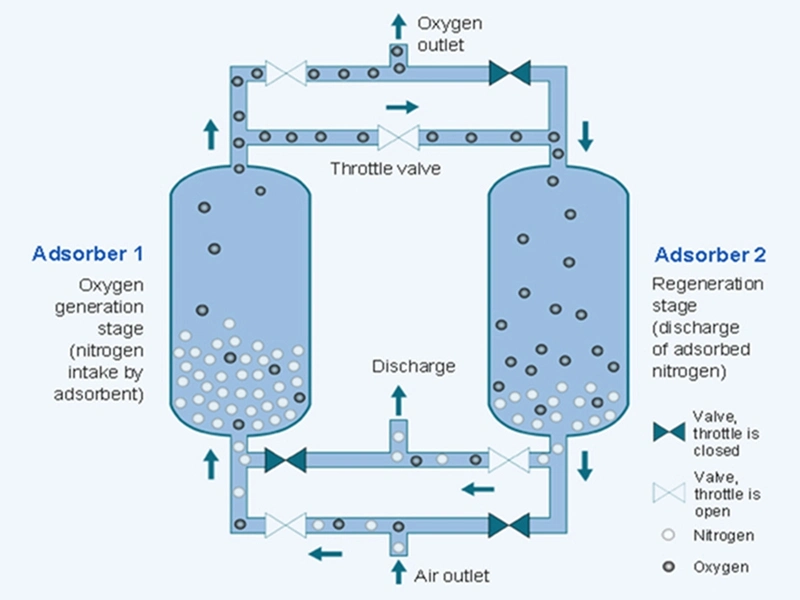

4. Working Principles for containerized oxygen generator oxygen plant

Air contains 21% Oxygen, 78% Nitrogen, 0.9% Argon and 0.1% other trace gases. Oxygen generator separates this oxygen from Compressed Air through a unique process called Pressure Swing Adsorption. (PSA).

The Pressure Swing Adsorption process for the generation of enriched oxygen gas from ambient air utilizes the ability of a synthetic Zeolite Molecular Sieve to absorb mainly nitrogen. While nitrogen concentrates in the pore system of the Zeolite, Oxygen Gas is produced as a product.

Oxygen generation plant's use two vessels filled with Zeolite Molecular sieve as adsorbers. As Compressed Air passes up through one of the adsorbers, the molecular sieve selectively adsorbs the Nitrogen. This then allows the remaining Oxygen to pass on up through the adsorber and exit as a product gas. When the adsorber becomes saturated with Nitrogen the inlet airflow is switched to the second adsorber. The first adsorber is regenerated by desorbing nitrogen through depressurization and purging it with some of the product oxygen. The cycle is then repeated and the pressure is continually swinging between a higher level at adsorption (Production) and a lower level at desorption (Regeneration).

-Standard features -

Control system with SIEMENS touch operated panel

Automatic start/stop

Built in purity analyzer for continues monitoring

Reliable - built for uninterrupted operation

Designed for dynamic pressure loading

Robust design, piping from Stainless Steel

Data-logging (saved on memory card)

-Optional features-

Molecular sieve moisture protection

GSM modem (remote start/stop, status SMS, alarm warning SMS)

Flow meter with totalize

Oxygen dew point sensor

Temperature sensor

Purity and pressure control

Audio/visual alarm

Modbus TCP/IP connection

Remote control

- Quality Control Process -

PB use ERP management system. The system keep management accounting as the core,which help plan and manage our company information,integrate all the internal resources, which help management of procurement, production, cost, inventory, distribution, transportation, finance and human resources. It universally helps to control and trace every process internally!

- Our Service-

1. Setting trace file for every sold product, quarterly survey for every sold product.

2. Providing remote instruction and training for free.

3. Providing on-site services and repairs for free during warranty period

4. Spare parts and on-site service would be charged with best price after warranty period.

5. 7*24 hours online service for free, solution within 48 hours.

6. If customer required, assigning experienced after-sales engineer for on-site service with 7 days. (Visa apply should be considered)

- Certificate-

- After Sales Support -

Warranty

The Guarantee/Warranty Period shall be a period of twelve months after on-site startup & commissioning or eighteen months after shipment, whichever occurs first. If any trouble or defect, originating with the design, material, workmanship or operating characteristics of any Goods, arises at any time during GUARANTEE/WARRANTY period, PB shall, at his own expense and as promptly as possible, make such alterations, repairs and replacements.

On-Site Support

PB can do paid services of on-site startup, commissioning, installation supervision, training, by providing purchaser with the services of qualified English-speaking

engineer at site.PB shall obtain all permits and licenses required to perform the services under this Agreement.

FAQ:

1. Are you manufacturer or Trade Company?

We are the manufacturer founded in 2015.

2. How to get a prompt quotation of Medical Oxygen Plant for Cylinder Filling?

When you send the inquiry to us, please kindly send it with below technical information.

1) O2 flow rate: _____Nm3/h

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/Hz

5) Application(Alititude, Humidty):

3. What's the order process ?

a. Inquiry---provide us all clear requirements.

b. Quotation---official quotation form with all clear specifications.

c. Contract confirmation---provide correct contract details.

d. Payment terms--- Negotiable.

e. Production---mass production

f. Shipping--- by sea, air or courier. Detailed picture of package will be provided.

g. Installation and debugging.

4.What terms of payment?

T/T, L/C etc.

Other Related Product

Thank you and welcome for inquiry ~